Factory Hygiene and Quality Initiatives

Hygiene Management

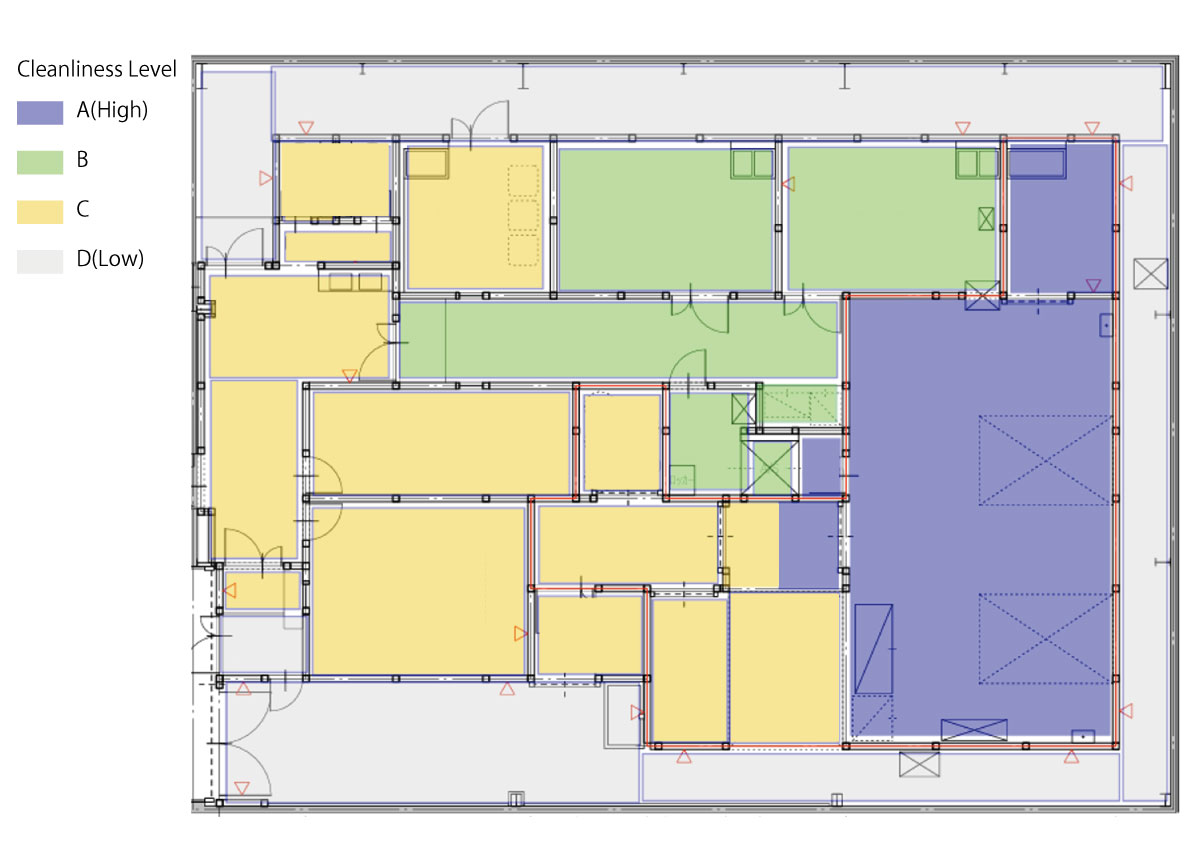

① Cleanliness control

We manage hygiene levels by area and control work flow lines to strictly maintain sanitary conditions, preventing foreign matter contamination, microbial contamination, and pests.

[Cleanliness Level A]

An area requiring strict cleanroom control.

The Ozonation Lab is controlled at Class 100,000.

Entry requires secondary change, hand washing, and passing through an air shower. Environmental monitoring is conducted.

[Cleanliness Level B]

There is no air-conditioning control or secondary changing area, but because this route leads into the manufacturing area, hand washing is performed, and the passage is separated by doors from Cleanliness Class C to Cleanliness Class B.

[Cleanliness Level C]

An area where work can be performed with primary change.

However, when entering the packaging room, hand washing, dust removal with a lint roller, and wearing a cap are required.

Cardboard boxes are not allowed to be brought in.

[Cleanliness Level D]

Outside of cleanliness control.

② Entry into the Production Area and Production Room (Secondary Change)

- When entering the production area [Cleanliness Level B], dust and lint on clothing must be removed using a lint roller, followed by hand washing.

Cardboard materials are prohibited. - When entering the production room [Cleanliness Level A], change into cleanroom garments, and wear a clean cap, gloves, and mask.

Switch to dedicated shoes, wash hands, and pass through the air shower before entering.

Upon entry, restrictions on personal belongings and health condition checks are implemented to prevent foreign matter contamination and ensure proper hygiene management.

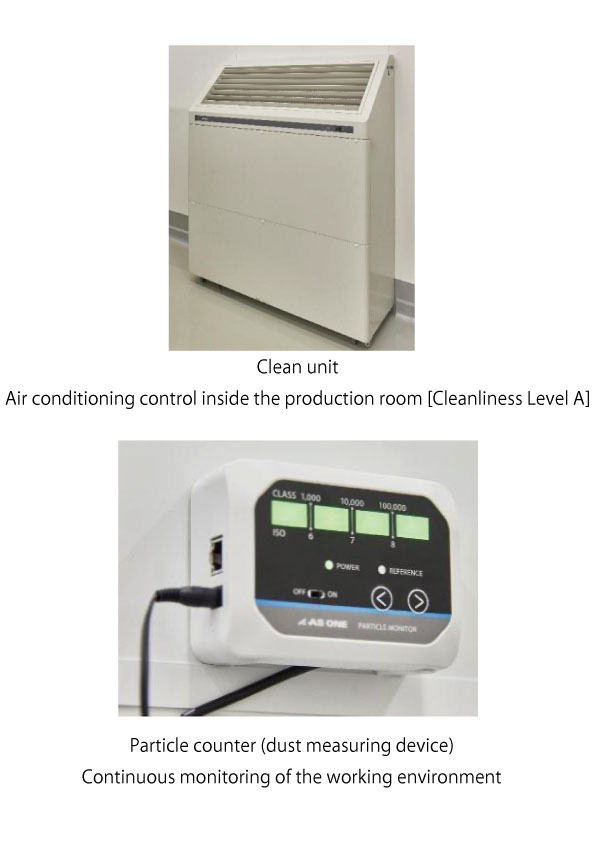

③ Cleanliness control

- To maintain Class 100,000, the area is controlled by clean units and continuously monitored using a particle counter.

- Insect traps are installed throughout the factory, and monthly pest monitoring is conducted by specialized service providers.

- Samples are passed through pass boxes to isolate the interior from external environments.

ManufacturingTechnology

Room temperature stabilization / Mass production

<Room temperature stabilization / Mass production>

By applying specific processing steps after ozonation glycerin, room temperature stability and scalable mass production have been achieved.

Safety and Quality Assurance

Exposure control / Quality inspection

【Exposure Control】

- Ozone gas leak alarm systems are installed to continuously monitor for any ozone leakage.

If leakage is detected, an alert is triggered and the equipment automatically shuts down. - During the ozonation process, ozone decomposers are installed to ensure that ozone is not released into the environment.

【Quality Inspection】

- A quality management system in compliance with GMP has been established, ensuring thorough quality checks from raw material acceptance through manufacturing and shipment.

- Standard operating procedures and record documents are maintained to standardize all operations.